About the skidder

Skidders are specialized forest articulated vehicles that are used for dragging timber on forest roads or forest wasteland. Timber is extracted with one end of the load lifted of the ground and leaned on the rear part of the vehicle, while the other part of the load is dragging on the soil. Besides equipping the skidder with a winch, various construction for loading wood is being developed: with a gripper facing downwards and with a gripper facing upwards and a crane for loading wood into the gripper. The basic features of all forest articulated tractors are articulated steering, all four drive wheels, and front axle load on about 2/3 of the total weight of the skidder. These technical characteristics of the skidder have enabled their better mobility and better performance in terms of forest exploitation.

In Croatia, the development of machinery and technology of wood production is particularly affected by specific features and characteristics of forest management, silvicultural system, and terrain configuration. Wood extraction is fully mechanized and it is done by forest vehicles (skidders and forwarders). On medium or steeply sloping terrains, in the area of the mountain and hilly forests, the long wood method is applied (half-tree and full-tree length) and wood is extracted by heavy skidders in regeneration and selective fellings, and small skidders in thinnings. In Croatia, the use of skidders began in 1968, in the 1970s a period of intensive mechanization began until the end of the 1980s when the required number of skidders was reached around 300. Due to the sylvicultural systems and diverse topographic conditions, cable skidders with wheels are primarily used. The advantage of using a winch on a skidder is that they move exclusively on forest roads and skid trails, which reduces damage to forest soil and remaining trees. The cable skidder does not have to take a position next to the cut tree or made wood assortments when forming the load because by using the winch there is a possibility of pulling the tree or wood assortment from the place of cutting and making to the tractor on the skid road.

Today, we have many manufacturers of skidders in the world, but we can define this family of vehicles with certain technical and construction features and the way of working that are identical for most types. The Skidder is a four-wheel articulated vehicle of equal dimensions, with a 4×4 drive formula. According to the design solutions, about 2/3 of the total weight is distributed on the front axle of the skidder.

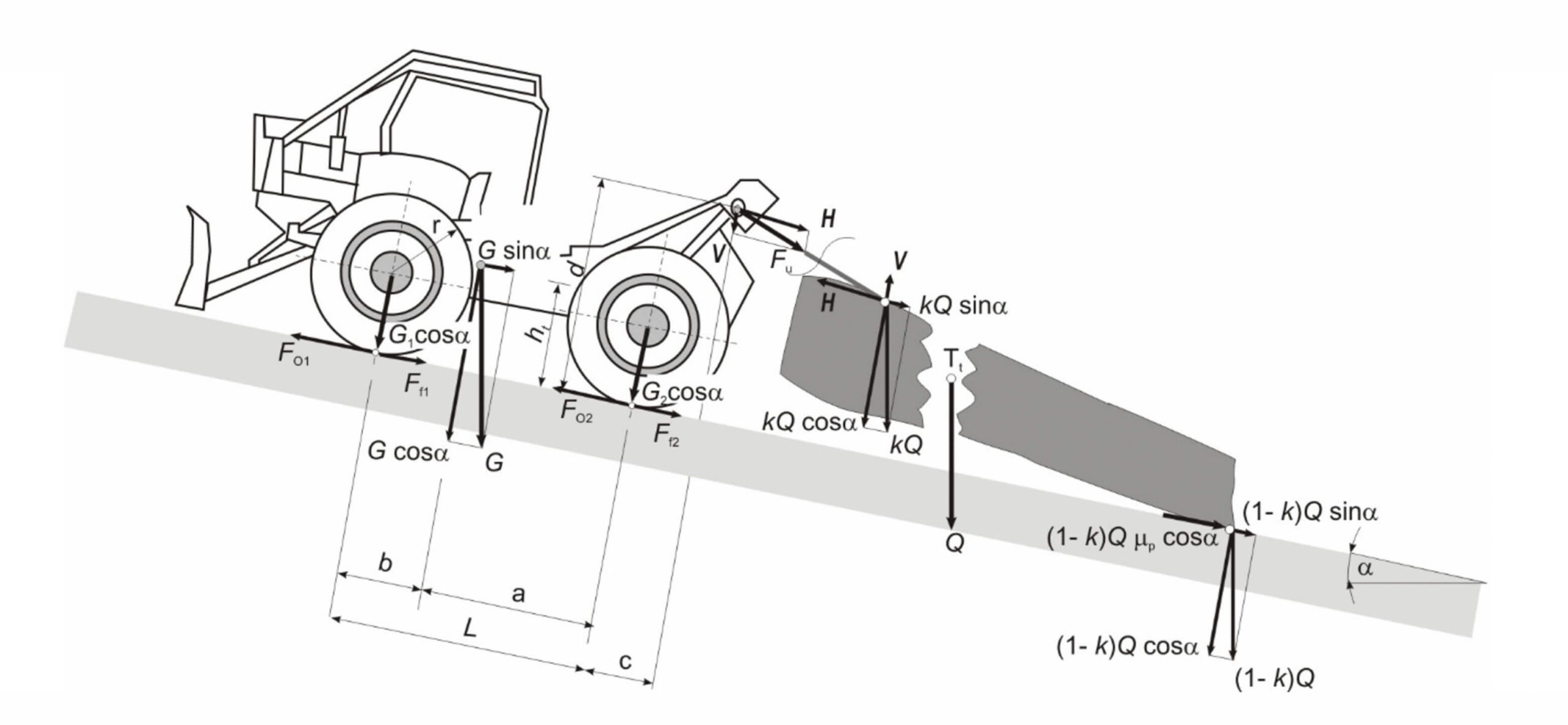

Such weight distribution of the skidder is necessary due to the method of operation for ensuring good longitudinal stability of the skidder. When pulling wood, the raised end of the load rests on the rear of the skidder and the dynamic loads of the front and rear axles are equalized or depending on the position of the wood in the load, the size of the load, and the slope of the terrain, the loads on the rear axle are higher.

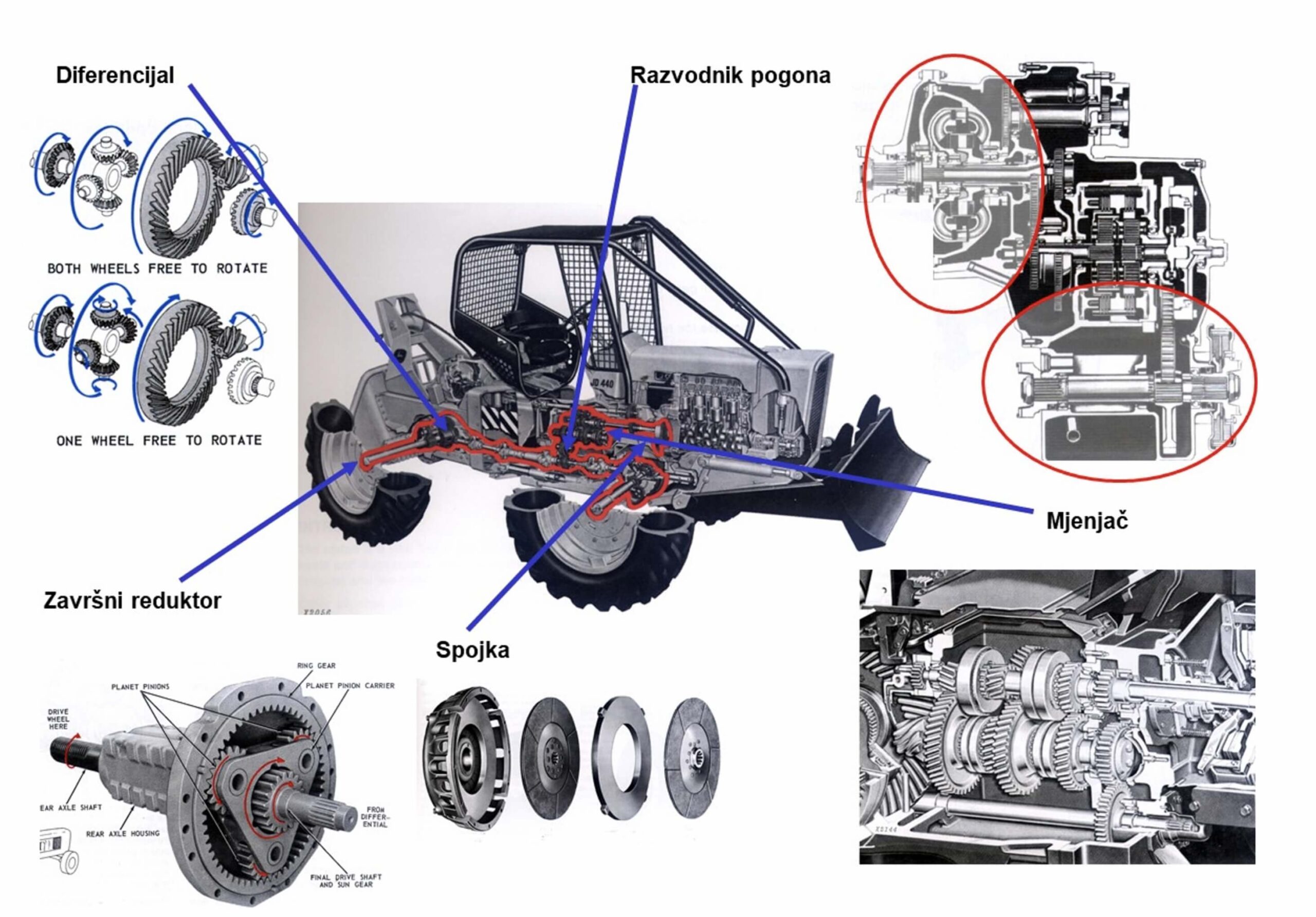

The chassis of the skidder consists of two separate frames. The front of the skidder has a built-in front axle with wheels, adjustable push-blade, engine, transmission, tarnsfer case, and cab, all attached to the front of the chassis frame. On the rear frame of the chassis, wheels are also placed over the semi-axles, and the necessary forest upgrade: forest winch, protective board, horizontal and vertical winch rollers. The front and rear frames are articulated with the possibility of joint movement, through hydraulic cylinders, only in the horizontal plane. The joint makes it easier to control the skidder in off-road conditions and a smaller turning circle, which improves the mobility of the vehicle. The kinematics of the skidder’s driving mechanism is such that the rear wheels follow the front wheels when turning. Increased lateral stability of the skidder when working on a slope or when crossing over surface obstacles is enabled by swinging front axle. The propulsion system consists of an internal combustion engine, most often a four-stroke diesel engine. The transmission system transmits power from the engine to all wheels. The transmission system consists of a clutch, gearbox, transfer case, differential on each axle, and a planetary or final gear on each wheel.

The cab of the skidder is made with protective constructions (protective frame and protective mesh) which, for the safety of the driver when overturning the vehicle or hitting an object (branch, log), must meet the strict criteria specified by ISO standards. A forest winch is installed at the rear of the skidder. The selection of winch is made based on the required nominal traction force and the total weight of the vehicle. As a rule, the rated traction force of the winch should not exceed the weight of the vehicle. The winch drive is usually hydraulic. The transmission of power to the winch is done by a shaft derived most often from the drive distributor to the winch itself in mechanical drive or the hydraulic pump in the hydraulic drive. All skidder equipped with a winch must have a protective rear bord. Rear protection board is used to support the raised log and protect the rear axle and wheels during skidding. The basic parts of the winch are the drum, the rope guides (horizontal and vertical rollers or pulleys), and the winch housing. The speed of the input shaft is to high for winch turning, therefore the speed is reduced by worm gear. Depending on the number of drums, there are single-drum and multi-drum winches Single-drum winches are used in the half-tree or full tree harvesting method, where there are a small number of pieces of wood in the load. Two-drum winches enable the tying of loads of a large number of pieces of wood, which is very effective in the assortment method of harvesting wood or when working in thinning fellings, when wood assortments or parts of a tree of smaller dimensions are winched. Winch control can be mechanical, hydraulic, or remote.